What Is The RCC Concrete And Properties of RCC Concrete

What Is The RCC Concrete And Properties of RCC Concrete

What Is The RCC Concrete And Properties of RCC Concrete

Reinforced Cement Concrete (RCC) is a composite material consisting of concrete and steel reinforcement. Concrete is known for its strength in compression but weakness in tension, which is why steel reinforcement is incorporated to enhance its tensile resistance. What Is The RCC Concrete And Properties of RCC Concrete.

In the realm of civil engineering, concrete is composed of various materials such as Cement, Sand, Mortar, Admixture, and more, with different grades based on strength.

The addition of steel reinforcement to concrete, creating RCC Concrete, is essential where higher tensile stress is anticipated. Steel is the preferred choice for reinforcement due to its superior tensile and bond strength, resulting in a robust concrete structure.

Steel’s high modulus of elasticity enables it to withstand significantly higher tensile forces with minimal extension compared to concrete.

Types of The Reinforcement Used In RCC Concrete

There are various types of steel reinforcement available in the market for construction purposes. Reinforcement bars, prestressing wires and strands, rolled steel sections, and light-gauge steel sections are the main forms of steel used in building construction.

Steel bars come in different shapes and grades, each with specific tensile strengths. These bars are used to reinforce concrete, ensuring good bond strength with the concrete, and are also utilized in the fabrication of grills, gates, and other structures.

Common types of reinforcement steel found in the market include mild steel, tor steel, and TMT bars. These bars are commonly used in reinforced concrete construction.

1 – Hot Rolled Steel.

There are four varieties of hot-rolled steel available in the market.

Mild steel bars, also known as MS bars, are the first type and are traditionally manufactured through hot rolling. These bars are hot rolled to form a round shape with a smooth surface, and are commonly referred to as mild steel plain bars.

Mild steel bars are categorized into two grades, Grade I and Grade II, with Grade I being slightly superior to Grade II. These bars exhibit greater resistance to corrosion compared to tor steel bars.

The second type consists of hot rolled mild steel ribbed bars, which feature ribs that enhance the bond strength of the bars.

Learn More

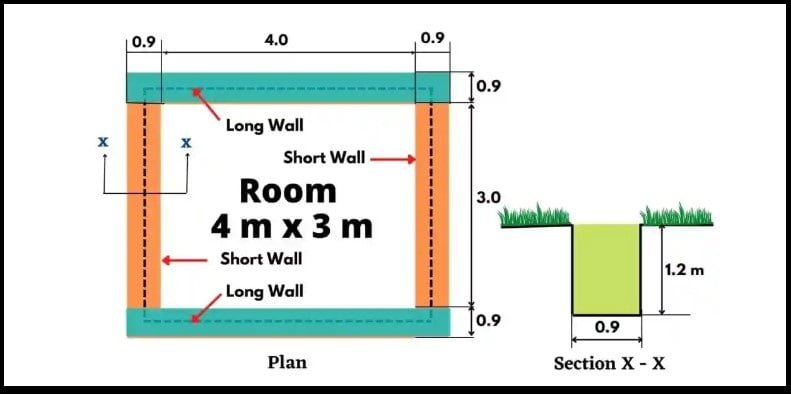

What is the Long Wall Short Wall Method

What is the Differences between Pillar and Column

Civil Engineering Interview Questions and Answers

Steel bars with rebar or ribbed bars, which can be mistaken for HYSD bars, are not recommended for use in R.C. works.

The third type is hot rolled high strength ribbed bars, which are produced through hot rolling and microalloying to achieve high strength.

Lastly, the fourth type is HYSD bars, which are hot rolled high yield strength deformed bars. These bars have now been replaced by TMT bars.

2 – Cold Twisted Deformed Bars (( Tor steel )).

Cold Twisted Deformed Bars, also known as Tor steel bars, were initially introduced as the first high-strength bars in India. These bars undergo a hot rolling process in the mill, resulting in the formation of high-grade mild steel with three or more parallel straight ribs.

Due to the straight line projection on the steel, it can be easily recognized in the field. Additionally, when cold twisted, these bars form a helical pattern around them.

However, it is important to note that this type of steel is more prone to corrosion and deteriorates at a faster rate compared to other bars. As a result, it is not recommended for use in many technologically advanced countries.

3 – TMT bars.

TMT, which stands for Thermo-mechanically Treated Reinforcement Bars, are produced by rapidly cooling red hot steel bars with a water spray. This process results in the formation of high-strength steel bars on the surface, while maintaining a mild steel core.

The TMT bars have a structure consisting of tempered martensite on the outer layer and a fine-grained ferrite-pearlite structure in the central zone. To enhance the bond strength, these bars are also manufactured with ribs.

In addition, TMT corrosion resistance steel (CRS) is available in the market. This type of TMT bar incorporates corrosion-resistant elements such as copper, phosphorus, and chromium to improve its resistance to corrosion.

When compared to Tor Steel, TMT bars exhibit superior corrosion resistance and are highly recommended for use in reinforced concrete projects.

These bars are manufactured in four different grades, namely Fe 415, Fe 500, Fe 550, and Fe 600.

4 – Welded Wire Fabrics.

Weldmesh, made from medium tensile steel extracted from mild steel bars, forms the basis of these fabrics.

The wire rolls of varying widths containing these fabrics are extensively utilized in applications such as partitions, fencing, and occasionally in the construction of R.C. slabs.

RCC must possess adequate compressive strength, along with sufficient tensile strength.

It should also exhibit high resistance to fire and weather conditions, ensuring durability.

Additionally, it should be economical to mold into various shapes and have low maintenance costs.

RCC is considered an economical construction material due to its durability, low deflection, and the ability to be used as precast structural components, requiring less skilled labor.

Uses of the RCC Concrete.

The utilization of RCC in construction is extensive and diverse.

It serves as the primary material for the structural framework of buildings, encompassing crucial load-bearing elements such as footings, columns, beams, chejjas, roofs, slabs, and stairs. Additionally, RCC finds application in the construction of storage facilities like water tanks, dams, bins, silos, and bunkers.

Its versatility extends to large-scale infrastructure projects, including bridges, retaining walls, docks, harbors, and underwater structures. Moreover, RCC is employed for the casting of precast elements like railway sleepers and electric poles. Furthermore, it is instrumental in the construction of towering structures such as multistory buildings, chimneys, and towers.

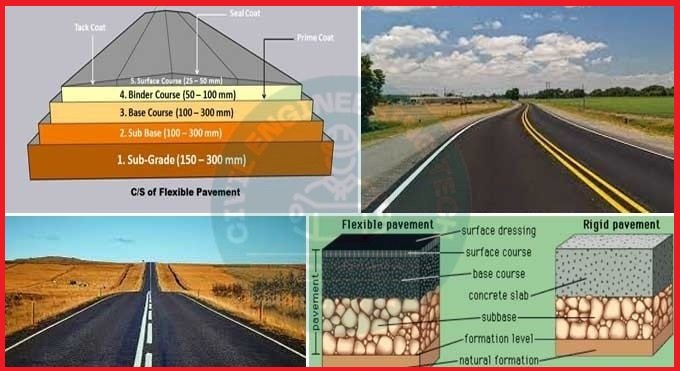

Lastly, RCC is utilized for paving work in the development of roads and airports.

Conclusion

In the conclusion reinforced cement concrete is the widely used construction material which combines the strength of the concrete and the tensile strength of the steel reinforcement, RCC is essential for building bridges, building dams, & foundations.

By utilizing mix proportions, sound construction practices, RCC structure can be constructed to be robust and the long lasting.

Learn More

RCC concrete, also known as Reinforced Cement Concrete, is a type of concrete that is strengthened by the inclusion of steel reinforcement bars (rebars) to increase its strength and durability.

The characteristics of RCC concrete consist of high compressive strength, good tensile strength, durability, fire and weathering resistance, and ease of construction.

The main difference between RCC concrete and plain concrete lies in the presence of steel reinforcement bars (rebars) in RCC concrete, which are utilized to enhance its strength and durability.

RCC concrete finds its applications in various sectors such as buildings, bridges, dams, tunnels, roads, and other infrastructure projects.

2 Comments