What is Best Practice in the Construction

What is Best Practice in the Construction

What is Best Practice in the Construction

The Best practices in the construction encompass the standard and meticulously planned approaches followed within the construction industry to the ensure optimal outcomes and profitability. These practices may take the form of the policies, procedures, or comprehensive systems implemented during specific periods. What is Best Practice in the Construction.

In the last 10 years, the construction industry has experienced notable transformations, thanks to the introduction of the innovative technologies and the development of new project procurement and management approaches.

Importance of the Following Best Practices in the Construction

The construction sector is the crucial and substantial part of the economy, employing more than seven% of the labor force and playing a significant role in national investment, which is the valued at $300 billion. A recent study conducted by BERL reveals that a mere ten% improvement in efficiency within this industry can result in a one% boost in the Gross Domestic Product (GDP).

Ten Best Business Practices in the Construction

- Procurement.

- Partnering.

- Risk Management.

- Value Management.

- Benchmarking.

- Supply Chain Management.

- Whole Life Costing.

- Health and Safety.

- Lean Construction.

- Sustainable Construction.

Read More

Derivation of formula to set out the curves by the method of ordinates from a long chord

Estimation of the Material for Concrete

Components of Road Structure

(1) – Procurement.

Procurement practices involve.

Opting for the suitable approach for managing construction projects.

Selecting the optimal team for designing, executing, and maintaining the facility.

Engaging in contracts that prioritize competitive pricing and fixed-sum agreements.

(2) – Partnering.

Collaborative partnering involves an approach to work that has been demonstrated to result in the several benefits:

- Enhanced cost-effectiveness.

- Heightened profitability for the organization.

- Advancements in quality.

- Assurance of project completion within expected timelines.

(3) – Risk Management.

The Risk management includes the maintenance of the risk register to monitor and address risks that arise during the course of the project. It is essential to conduct regular risk assessments and analyses, and to set aside financial resources to cover any remaining risk factors.

(4) Value Management.

The Value management takes into account time, cost, and risk limitations in the order to fulfill clients’ business requirements. This approach highlights the importance of teamwork within the project group, involving end-users and stakeholders, to assess and select alternatives that meet client needs.

Read More

What is contour interval and Uses of contour maps in surveying

how to Calculate the height of an object using With theodolite

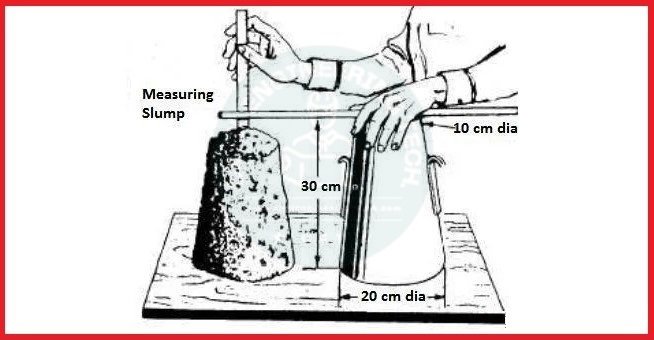

Concrete Slump Test workability Procedure and result

What Is The RCC Concrete And Properties of RCC Concrete

(5) Benchmarking.

The Benchmarking is a method used to analyze the performance of the past projects in order to enhance the efficiency of upcoming projects in a structured manner. It places emphasis on key factors including environment, time, cost, quality, safety, productivity, and profitability.

(6) – Supply Chain Management in the Construction.

The Supply chain management in the construction industry entails the seamless integration of all activities involved in delivering the product or service, spanning from the initial producers to the ultimate end-users. The implementation of the efficient supply chain management practices not only facilitates cost savings but also enhances the overall value, necessitating a combination of the operational and managerial approaches.

(7) – Whole Life Costing.

The Whole life costing evaluates the complete expenditure associated with owning the structure, encompassing the initial capital outlay, ongoing maintenance, and servicing expenses. This approach recognizes the significance of maintenance costs surpassing the initial capital investment and plays a vital role in the making well-informed decisions.

(8) – Health & Safety in the Construction Project.

The Health and the safety practices in the construction prioritize protecting workers’ rights and ensuring effective planning and management of the construction sites to enhance productivity and profitability. Proper planning, training, supervision, and provision of the necessary equipment are essential.

Read More

(9) – Lean Construction Practice.

The Lean construction focuses on minimizing or eradicating processes that increase expenses, with a focus on delivering value. The core principles of the lean construction involve determining value from the customer’s point of view, incorporating processes that deliver value, producing necessary items just in time, pursuing ongoing enhancements, and enabling uninterrupted value flow.

(10) – Sustainable Construction.

The Sustainable construction aims to improve the social, economic, and the environmental aspects of the industry. It involves strategies such as optimizing profits, constructing buildings that provide higher satisfaction and value, ensuring equitable treatment of the workers, reducing waste and pollution, and advocating for energy-efficient structures that rely on renewable resources.

Other Post

Civil Engineering Interview Questions and Answers

Calculation of Bricks and Blocks in the Wall

Civil Engineering Basic Field Knowledge

Thank You For Reading This Important Information. Get Benefits And Share With New Commers.

4 Comments