Foundation Backfilling types and Procedure

Foundation Backfilling types and Procedure

What is the Backfilling?

Backfilling is a crucial procedure in construction, vital for reinforcing and stabilizing the foundations and structural elements of buildings. This process entails the replacement or repurposing of excavated soil to maintain the structural integrity of a project.

Factors affecting Backfilling in the Foundation.

Several factors play crucial roles in backfilling process

(1) Selection of the Appropriate Backfill Material

The selection of backfill material is crucial, as it significantly affects the stability and durability of the structure. The materials available vary from coarse-grained soils to industrial by-products such as furnace slag or fly ash, each with unique properties that make them appropriate for particular uses.

Learn More

Direct Method of Linear Measurement In Surveying

Classification of Road Markings

What is Concrete Compaction factor test

(2) Compaction of Backfill

Adequate compaction of backfill material is essential to avoid settling and to provide consistent support for the foundation. The techniques employed for compaction require the utilization of heavy machinery and meticulous engineering to attain the specified density levels.

(3) Timing of Backfilling

The timing of backfilling is essential to ensure sufficient curing of the foundation. If backfilling occurs too early, it may result in structural problems like cracking, highlighting the importance of exercising patience and following the suggested curing durations.

Types of Backfilling in the Foundation.

Backfilling materials can be classified into several categories according to their composition and properties.

Course Grained Soil

These consist of gravelly and sandy soils, which provide outstanding drainage characteristics and significant load-bearing strength, making them suitable for improving the stability of foundations.

Fine-Graded Soils Of the Low To Medium Plasticity

Organic clays and inorganic silts characterized by low to medium plasticity are employed in regions where cohesive strength and stability are critical, thereby guaranteeing reduced settlement and deformation.

Learn More

How To Measurement of Horizontal Distance Using Auto Level

Reinforcement Of The Isolated Footing

How To Calculate the Quantity Of Concrete Volume Of Staircase

Commercial By-Products

Furnace slag and fly ash present effective substitutes for natural backfill materials, providing both environmental advantages and cost savings when they are readily accessible in the local area.

CLSM (Controlled low strength material)

CLSM offers a self-compacting, flowable, low-strength cementitious solution suitable for backfilling, void filling, and utility bedding, ensuring both versatility and ease of application.

Steps involved in backfilling in the foundation

(1) Preparation

It is essential to allow the foundation to cure properly prior to initiating backfilling, generally waiting for a period of five to seven days to reduce the likelihood of structural defects.

(2) Site Preparation

Remove debris, vegetation, and excess water from the site to establish an appropriate foundation for backfilling.

(3) Material Selection

Select a well-proportioned combination of materials, such as excavated soil, rocks, and stones, while taking into account aspects like moisture retention and structural integrity.

Learn More

Find out the quality of Cement on the site

What is Difference between Plinth Beam and Tie Beam

How to Create the Bar Bending Schedule Of Slab

Bar bending schedule for footing

(4) Layered Backfilling

Utilize a stratified method for backfilling, ensuring that each layer is adequately compacted and moistened to attain maximum density and consistent support.

(5) Equipment Utilization

Employ robust equipment, including excavators and compactors, to effectively fill and compact the backfill material, guaranteeing uniform distribution and compaction across the foundation site.

(6) Quality Control

Consistent evaluation and compliance with established specifications are essential to avert problems such as settlement or insufficient support. There are stringent regulations prohibiting the use of inappropriate materials, such as black cotton soil, in vital foundation zones.

Other Post

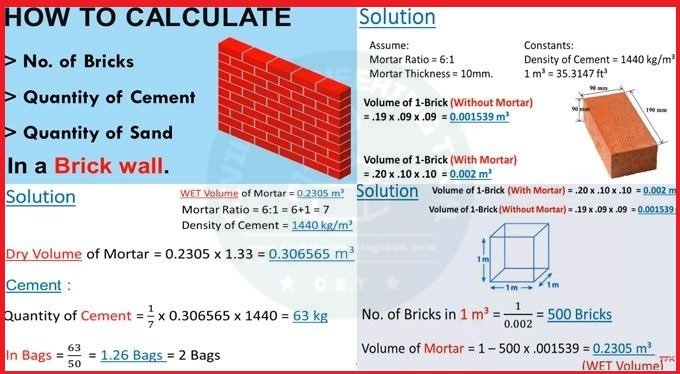

Estimation of the Material for Concrete

Components of Road Structure

how to Calculate the height of an object using With theodolite

Concrete Slump Test workability Procedure and result

Thumb rule for Civil Engineers

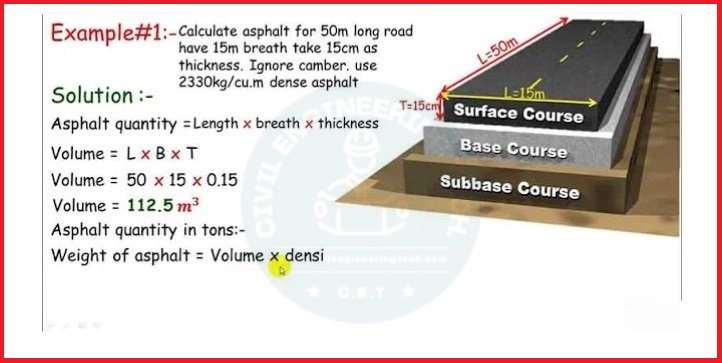

How To Calculate the Asphalt Quantity For Road

One Comment