Concrete Slump Test workability Procedure and result

Concrete Slump Test workability Procedure and result

The concrete slump test, also known as the slump cone test, is conducted to assess the workability or consistency of the concrete mix. This test is performed either at the laboratory or on-site during the construction process.

Its purpose is to ensure the uniform quality of the concrete throughout the construction project. The slump test is a straightforward and cost-effective method that yields immediate results. Consequently, it has been widely employed for workability assessments since 1922. Concrete Slump Test workability Procedure and result.

The procedures for conducting the slump test are outlined in ASTM C143 in the United States, IS: 1199 – 1959 in India, and EN 12350-2 in Europe. Typically, the concrete slump value is utilized to the determine workability, which is the indicative of the water-cement ratio. However, other factors such as material properties, mixing techniques, dosage, and admixtures can also influence the concrete slump value.

The Different factors that affect the concrete slump test can be identified.

The Material properties like chemistry, fineness, particle size distribution, moisture content and temperature of the cementitious materials. Size, texture, combined grading, cleanliness and the moisture content of the aggregates.

Read More

What is contour interval and Uses of contour maps in surveying

how to Calculate the height of an object using With theodolite

What Is The RCC Concrete And Properties of RCC Concrete

The Chemical admixtures dosage, type, combination, interaction, sequence of the addition & its effectiveness.

Air content of the concrete.

The Concrete batching, mixing, transporting methods & equipment.

Temperature of concrete.

Sampling of the concrete, slump-testing technique and the condition of the test equipment.

The amount of the free water in the concrete and time since mixing of the concrete at the time of testing.

Which Equipment’s Required for the Concrete Slump Test

The equipment required for the conducting a slump test includes a slump cone, a non-porous base plate, a measuring scale, and a tamping rod.

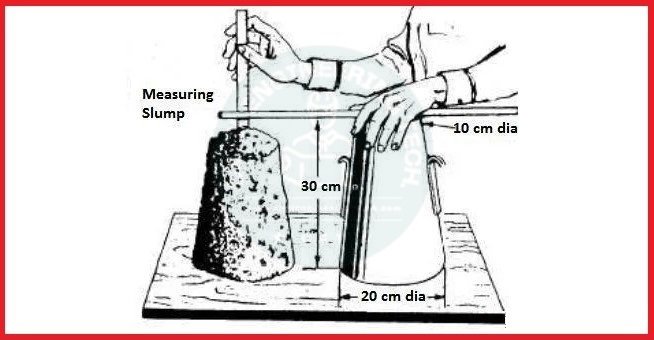

The mold used for this test is shaped like a frustum of the cone, with a height of 30 cm, a bottom diameter of 20 cm, and a top diameter of ten cm. The tamping rod, which is used to compact the concrete, is made of steel and has a diameter of sixteen mm and the length of 60 cm. It is rounded at 1 end.

Sampling of the Materials for Slump Test

The laboratory prepares a concrete mix (such as M15) by weighing the ingredients and ensuring a suitable water/cement ratio. This process is similar to the one described in the section 5.9 and is necessary for casting six cubes after conducting a Slump test.

Procedure for the Concrete Slump Cone Test

- Clean the interior of the mold and apply oil.

- Position the mold on a flat, horizontal, non-porous base plate.

- Pour the concrete mix into the mold in approximately four equal layers.

- Compact each layer by tapping it 25 times with the rounded end of the tamping rod, ensuring uniformity across the mold’s cross-section. For subsequent layers, the tamping should reach into layer below.

Read More

What is the Long Wall Short Wall Method

What is the Differences between Pillar and Column

Civil Engineering Interview Questions and Answers

Remove any excess concrete and level the surface with a trowel.

- Clear away any mortar or water that may have leaked between the mold and the base plate.

- Lift the mold vertically and immediately from the concrete.

- Measure the slump by calculating the difference between the height of the mold and the highest point of the specimen being tested.

Note

Please ensure that the aforementioned procedure is the conducted in a location devoid of any vibrations or shocks, and completed within a timeframe of two minutes following the sampling process.

What is the Results of Slump Test on Concrete

The concrete slump shape that can be observed during the slump test is as follows: Slump for the provided sample = _______mm.

(1)True Slump

The True slump is the only slump that can be measured in test. The measurement is taken between top of cone & top of the concrete after the cone has been removed as shown in the figure-1.

(2) Zero Slump

Zero ( 0 ) slump is the indication of the very low water-cement ratio, which results in the dry mixes. These type of the concrete is generally used for the road construction.

Read More

(3) Collapsed Slump

This is an indication that the water-cement ratio is too the high, i.e. concrete mix is too wet or it is the high workability mix, for which the slump test is not appropriate.

(4) Shear Slump

The shear slump indicates that the result is incomplete, and the concrete to be retested.

Other Post

Derivation of formula to set out the curves by the method of ordinates from a long chord

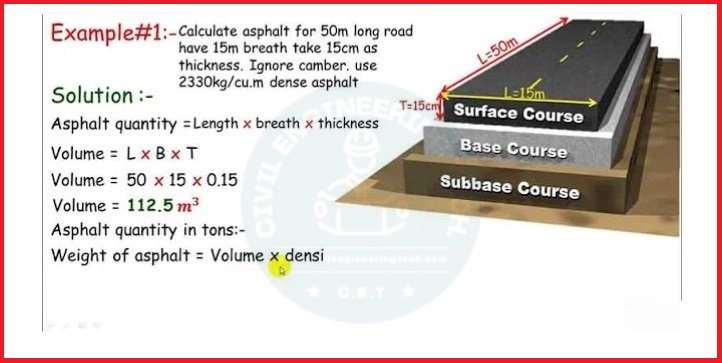

Estimation of the Material for Concrete

Components of Road Structure

One Comment