Bar Bending Schedule for Beam

In this article, we will discuss the process of creating a bar bending schedule for a Beam, also known as BBS for Beam. Bar Bending Schedule for Beam.

We will now proceed with the preparation of Bar Bending Schedule (BBS) for a beam in 2 different types.

- The first type is the BBS for a simple beam, which is typically used on-site.

- The second type includes various details as illustrated in the corresponding diagram.

BBS for Simple Beam

The diagram illustrates a beam with a clear span of 3 meters, comprising 2 numbers of 16 mm diameter bars at the bottom and 2 numbers of 12 mm diameter bars at the top, along with 8 mm diameter stirrups at 150 mm clear cover.

This configuration is based on a clear cover of 25 mm at both ends and sides of the beam.

Observations;

- Clear Span of the Beam = 3000 mm

- Development Length Ld = 50d (assumption)

- Clear Cover on any ends = 25 m

- Bottom – Two numbers of 16⌀

- Top – Two numbers of 12⌀

- Stirrups – 8⌀ @ 150mm clear cover

Read More

deflection angle in surveying

What is Difference between Plinth Beam and Tie Beam

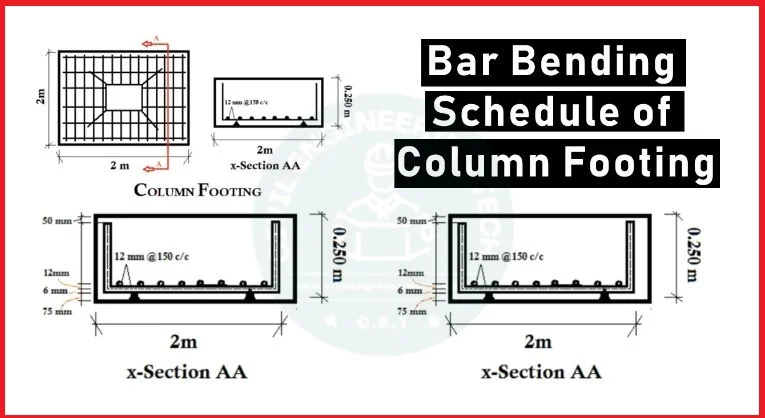

Bar bending schedule for footing

Step No 1 – Find the cutting length of top bar

Cutting length of the top bar = Clear Span of the Beam + Development length (Anchorage) Ld on Two sides – Clear Cover on Two ends

= 3000+(2 x 50d) – Two x 25 = 3000 + (Two x 50 x 12) – Fifty

= 4150 mm

Step No 2 – Find the cutting length of bottom bar

Cutting length of the bottom bar = Clear Span of the Beam + Development length (Anchorage) Ld on Two sides – Clear Cover on Two ends

= 3000+(Two x 50d) – 225 mm = 3000 + (Two x 50 x 16) – 50

= 4550 mm

Step No 3 – Find out Number of the Stirrups

Number of the Stirrups required = (Clear Span of the Beam/Spacing Stirrups)+ One

= (3000 / 150) +One = 21 No.s

Step No 4 – Find out the cutting length of Each Stirrup

Let’s split the sides as (a, b) for the easy calculation.

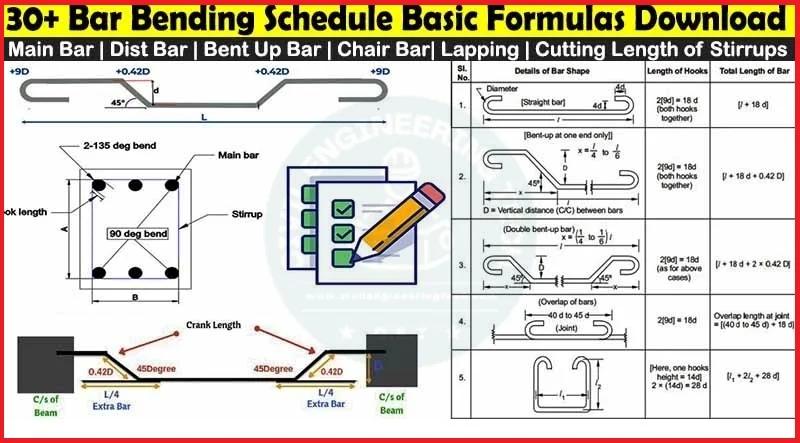

Length of the 1 Hook = 9d (As per the Estimating and Costing in the Civil Engineering P.No.214)

Cutting length of the Stirrup = Perimeter of the stirrup + Number of the Bends + Number of the Hooks

= Two (a+b) + 3 numbers of 90 degree bends + Two numbers of hooks

= 2(300+500) + (three x 2d)+(Two x 9d) = 1600 + (3 x Two x 8) + (2 x Nine x 8) = 1792 mm

| Diameter of Bar | Numbers | Cutting Length | Total Length | |

| Top Bar | 12 | Two | 4150 mm | 8300 mm |

| Bottom Bar | Sixteen | Two | 4550 mm | 9100 mm |

| Stirrups | Eight | 21 | 1792 mm | 37632 mm |

BBS for Detailed Beam

As u can see that this diagram has more detailed and the technical implementation of the design aspects.

Now started;

The above beam has the clear span of Six metre consists of the 2 layers of bottom (Two numbers of 20mm dia) and 1 layer of the top (Two numbers of the 12mm dia).

It consists of three Zones where Zone One, Three has stirrups of 150 mm spacing and Zone two has stirrups of 200 mm spacing.

Observations

- Clear Span of the Beam = 6000 mm

- Development Length Ld = 50d (assumption)

- Clear Cover on any ends = 25 mm

- Bottom – four numbers of 25⌀

- Top – two numbers of 12⌀

- Stirrups

- zone one, three = 8⌀ @ 150mm clear cover

- zone Two = 8⌀ @ 200mm clear cover

Step No 1 – Find the cutting length of top bar

Cutting length of the top bar = Clear Span of the Beam + Development length (Anchorage) Ld on two sides – Clear Cover on two ends

= 6000+(2 x 50d) – two x 25 = 6000 + (Two x 50 x 12) – Fifty

= 7150 mm

Read More

Step No 2 – Find the cutting length of bottom bar

Cutting length of the bottom bar = Clear Span of the Beam + Development length (Anchorage) Ld on two sides – Clear Cover on two ends

= 6000+92 x 50d) – two x 25 = 6000 + (two x 50 x 25) – Fifty

= 8450 mm

Step No 3 – Find out the Number of Stirrups

As we said this beam has 3 types of zones where Zone One & three has stirrups has 150 mm spacing and Zone three has 200 mm spacing.

1st calculate the length of the zones = L/3 = 6/3 = Two metre.

Number of the stirrups required for Zone One = (Clear Span of the beam/ spacing Stirrups)+ One

= (2000/150)+One = 14.3 ♎ Fourteen no.s

Number of the stirrups required for Zone three = same as Zone One = 14 no.s

Number of the stirrups required for Zone Two = (Clear Span of the beam/ spacing Stirrups) – One = (2000/200)-One = Ten no.s

The reason for the “minus One “ is already zone One has end stirrup so we don’t need to again start from new 1. we just continue the stirrups already existing with the extra spacing.

Step No 4 – Find out the cutting length of Each Stirrup

Length of the 1 Hook = 9d (As per the Estimating and Costing in the Civil Engineering P.No.214)

Cutting length of the Stirrup = Perimeter of the stirrup + Number of the Bends + Number of the Hooks

Read More

What is Best Practice in the Construction

Thumb rule for Civil Engineers

How To Calculate the Asphalt Quantity For Road

= 2(a+b) + Three numbers of 90 degree bends + Two numbers of the hooks

= 2(300+500) + (three x 2d)+(Two x 9d) = 1600 + (3 x Two x 8) + (2 x Nine x 8) = 1792 mm

| Diameter of Bar | Numbers | Cutting Length | Total Length | |

| Top Bar | 20 | Two | 7150 mm | 14300 mm |

| Bottom Bar | 25 | Four | 8450 mm | 33800 mm |

| Stirrups | Eight | 21 | 1792 mm | 37632 mm |

We hope this post is very important and useful for you.