Civil Engineering Basic Field Knowledge

Important Points for The Civil Site Engineers

In the construction civil engineers doing many activities and facing quick site construction problems for solution of this problem the civil engineers must remember these points, tips & the tricks. There are general tips, tricks & tables for the civil engineers to remember it and make the construction work easier. If the quality of the construction is good. The important and basic field knowledge for civil engineers are given below. Civil Engineering Basic Field Knowledge

Basic Points for the Civil Engineer

The basic Field knowledge and important points for the civil engineer is given below

- Minimum thickness of the slab must not be less than 125 mm.

- For the normal construction the size of coarse aggregate ranges from ten to 20 mm.

- Lapping of the bar must not be used having diameter more than thirty Six mm.

- The height of the floor to floor should not be less than three m and not more than Four m.

- Water absorption of the bricks should be less than fifteen %

- The combination of the cement, sand & coarse aggregate should be according to design.

- PH value of the water should not be less than Six because below the PH value of Six it is acidic.

- For calculation of the unit weight of steel, the formula is D 2/162.162 in Kg/m. this formula is used when the dia of the bar is in mm. while for lb/ft the formula is used D 2/52.9 where dia of the steel is in sootar.

- The Concrete cover should be sufficient

- The compressive strength of the brick is 3.5N/mm.

- The Concrete should not be fall from more than 1.5 m height.

- Don’t use over vibrator in the concrete.

- For dowel bars the dia of the steel should not be less than twelve mm.

- For chair bar the dia of the steel should not be less than twelve mm

- Formwork should be tight.

- The longitudinal bars should not be less 0.8 % & not more than Six % of gross c/s.

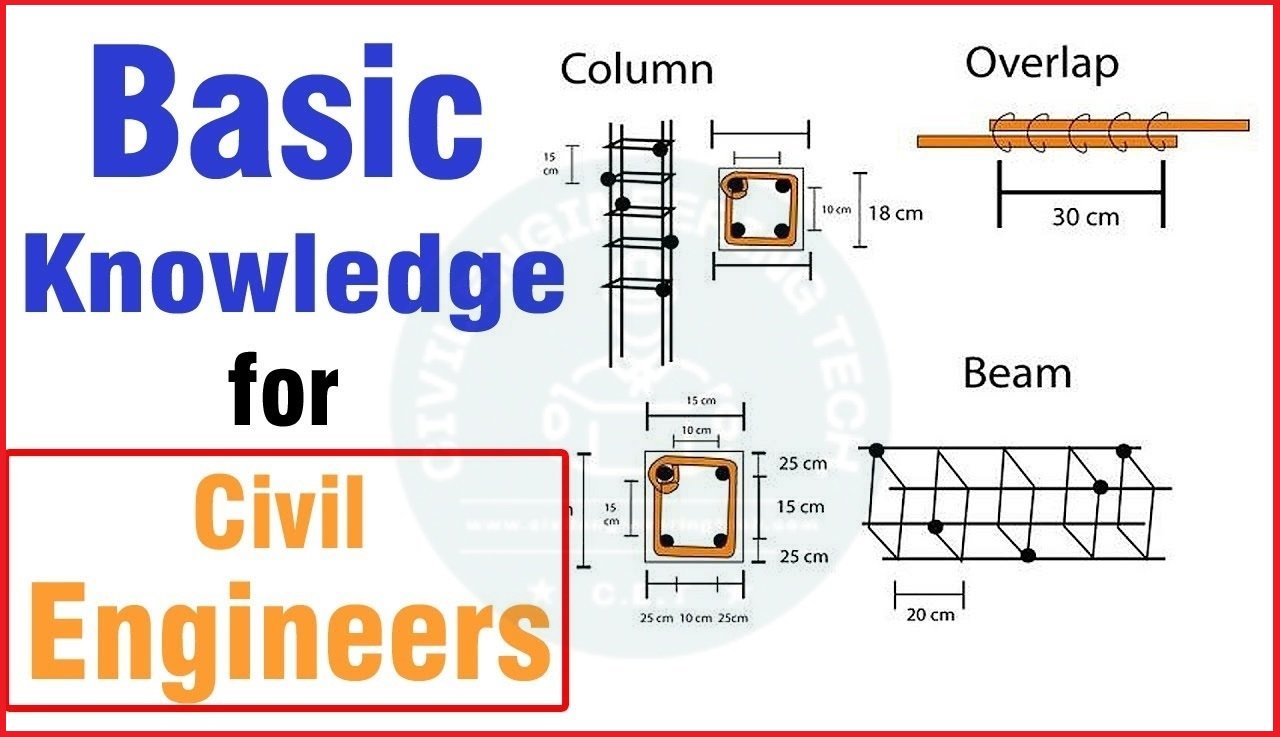

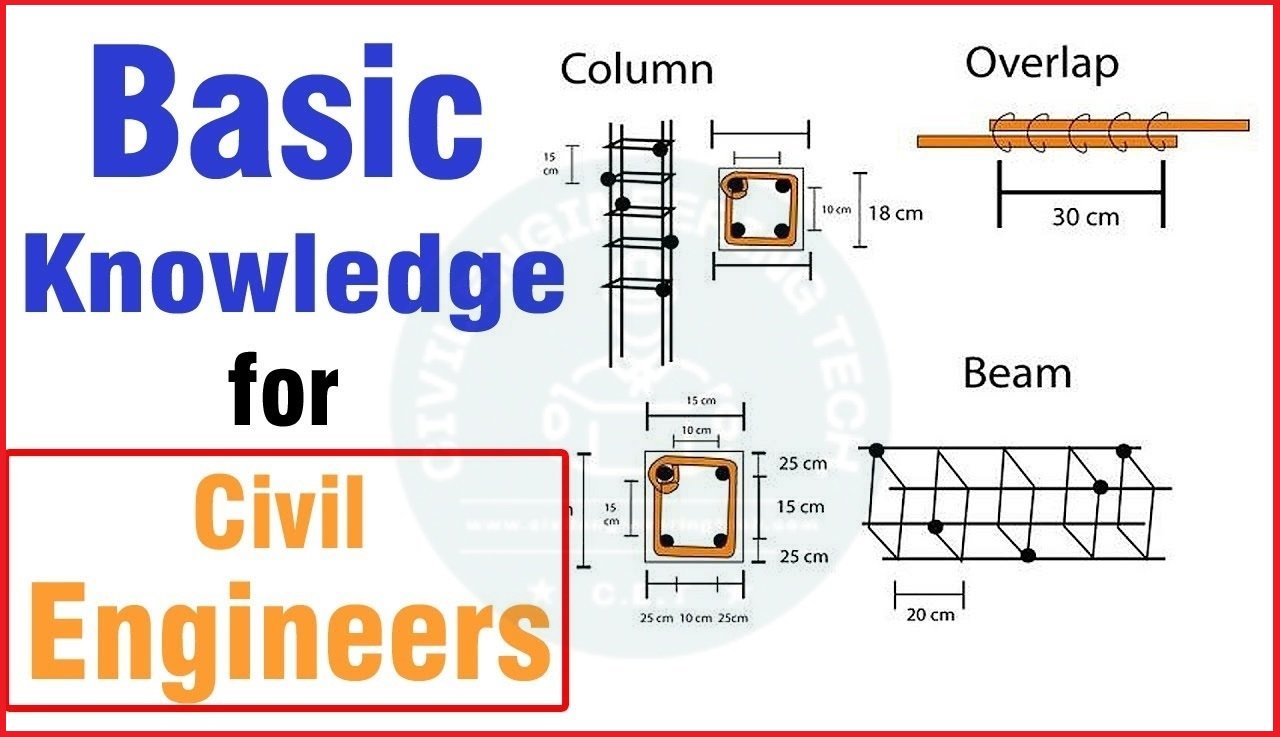

- The minimum number of the bars in circular column is Six No’s. while in square column the number of the bars is Four No’s.

- Cement should be stored in the dry place. It would be raised from the Eight inches above floor level & 1 (One) foot or 300 mm away from each side of the walls. The cement bags should be stocked more than Ten bags in such a manner.

- The Electrical conduits shall not run in the column or beam.

- In the steel construction the binding wire required is Eight Kg per MT.

- The spacing between chair bars should not be more than One meter or 1 chair bar per One m2

- The dimension tolerance for cubes +, – Two mm.

- Earth quick excavation for the basement above Three m should be steeped form

- Water cement ratio must be check.

- Water cement ratio is the different for different grade of the concrete for example water cement ratio should be 0.45 for M20, M25 & above. 0.50 for M15, M10 and below.

- The cube test should be done for every thirty cubic meter (m3) area.

- The aggregate which are used in the concrete must be free from silt, dust & clay or other impurities.

- In the aggregate the angular shape is good for the construction. In angular shape aggregates it makes the bond perfect & concrete is prepared from it very strong and have high strength.

- In the soil filling as per IS code for every hundred square meter (m2) three sample for core cutting test should be taken.

- The compaction of the concrete should be done properly.

- Concrete should be transport to shortest route.

- Reinforcement design should be done according to as per IS codes.

Learn More

How to Calculate the Bricks and Blocks in the Wall

Density of the Materials

Materials have not same density. The density is different for the different materials density of materials is given below:

S. No | Materials | Density in Kg / m3 |

| 1 | water | 1000 |

| 2 | cement | 1440 |

| 3 | Plain cement Concrete | 2400 |

| 4 | Reinforcement concrete | 2500 |

| 5 | Asphalt | 721 |

| 6 | lime | 640 |

| 7 | Lime mortar | 1760 |

| 8 | iron | 7850 |

| 9 | steel | 7850 |

| 10 | Aluminum | 2739 |

| 11 | Glass | 2580 |

| 12 | Zinc | 7135 |

| 13 | Lead | 11340 |

| 14 | Tin | 7280 |

| 15 | Nickle | 8908 |

| 16 | Copper | 8940 |

| 17 | Magnesium | 1738 |

| 18 | Stainless steel | 8000 |

| 19 | Igneous rock | 2700 |

| 20 | Sedimentary rock | 2600 |

| 21 | Metamorphic rock | 2700 |

| 22 | Sandstone | 2000 |

| 23 | Bricks | 1500 – 1800 |

| 24 | Clay soil | 1900 |

| 25 | Bamboo | 350 |

| 26 | Aspen | 420 |

| 27 | Ash (black ) | 540 |

| 28 | Ash ( white) | 670 |

| 29 | Sandy soil | 1800 |

| 30 | Pine | 500 |

Concrete Cover or Clear Cover to the Reinforcement Bar

The Concrete cover is used to protect the rebar against corrosion & to provide resistance against fire. The thickness of the concrete is various in different members of the structure. The chart or table for the concrete cover to reinforcement bar is given.

S. No | Member of the structure | Concrete cover in (mm) |

| 1 | Beam | 25 |

| 2 | Slab | 15 |

| 3 | Stair case | 15 |

| 4 | Column | 40 |

| 5 | Raft foundation Sides | 75 |

| 6 | Footing | 75 |

| 7 | Raft foundation bottom | 75 |

| 8 | Water retaining structures | 25 |

| 9 | Shear wall | 25 |

| 10 | Flat slab | 20 |

| 11 | Grade slab | 20 |

| 12 | Raft foundation top | 50 |

| 13 | Strap beam | 50 |

Curing Method of the Concrete.

The curing method of the concrete is given below

- spraying

- ponding

- steam curing

- wet covering

- curing chemicals

Cube Samples for the Different Quantity of the Concrete Volume.

The Cube sample is used to find the compressive strength of the concrete u should find different number of samples for different volume of the concrete. The cube samples for different qty of the concrete volume is follow.

S. No | Volume of Concrete | Number of the samples |

| 1 | 1 to 5 m3 | one sample |

| 2 | 6 to 15 m3 | two samples |

| 3 | 16 to 30 m3 | three samples |

| 4 | 30 to 50 m3 | four samples |

| 5 | 50 plus or above 50 m3 | five samples |

Removal of the Formwork or De Shuttering Time.

There are different members of the formwork such as foundation, beam, column & slabs etc. after poring of the concrete the shuttering should be remove after some time the time of de shuttering is given below.

S. No | Members of structure | Days |

| 1 | Sides of the foundation, beam, columns and walls | Two days |

| 2 | Sides of the slab under 4.5 meter span | Seven days |

| 3 | Sides of the slab above 4.5 meter span | Forten days |

| 4 | Side of the beams and arches up to Six meter span | Forten days |

| 5 | Side of the beams between Six meter to 9 meter span | Twenty One days |

| 6 | Side of the beams and arches above Nine met | Twenty Eight days |

Weight of the Steel Bar per M/Kg

The weight of the steel bar in meter per kilogram is given in table below.

S. No | Dia of bar in (mm) | Weight of steel in Kg per meter |

| 1 | Six | 0.22 |

| 2 | Eight | 0.39 |

| 3 | Ten | 0.61 |

| 4 | Twelve | 0.88 |

| 5 | Sixteen | 1.57 |

| 6 | Twenty | 2.46 |

| 7 | Twenty Five | 3.85 |

| 8 | Thirty Five | 6.31 |

| 9 | Forty | 9.86 |

Note:

The formula of used in this table is D2/162.162 in Kg/m. this formula is used when the dia of the bar is in mm and length of the bar in meter.

Conversion of the Units.

The conversion of the units is used by every civil engineers on site to make calculation good and quickly. The conversion of units is given below:

| One secra = 100 ft3 | One pole = 1 perch |

| One foot = 12 inches | One yard = 3 ft |

| One foot = 0.304 meter | One yard = 36 inches |

| One foot = 304.8 mm | One yard = 0.914 meter |

| One foot = 30 cm | One yard = 91.44 centimeter |

| One mile = 1.609 km | One yard = 9144 millimeter |

| One millimeter = 0.039 inch | One karam 5.5 ft |

| One inch = 25.4 mm | One karam = 1.67 meter |

| One inch = 2.54 centimeter | One Marla = 272.72 square feet |

| One furlong = 600 ft | One Marla = 25.10 square meter |

| One foot = 0.36 vars | One kanal = 20 Marla |

| One furlong = 40 rods | One kanal = 502 square meter |

| One mile = 8 furlong | One kanal = 180 square karam |

| One mile = 320 rods | One acre = 160 square rods |

| One mile = 800 links | One acre = 160 poles |

| One mile = 80 chains | One acre = 0.4047 hectare |

| One mile = 320 perches | One Acre = 100 square meter |

| One mile = 5280 ft | One link = 7.92 inches |

| One perch = One pole | One link = 0.66 foot |

| One perch = One rod | One link = 0.20 meter |

| One perch = 16.5 ft | One N = 0.101 kg |

| One rod = One perch | One kg = 9.8 N |

| One perch =25 links | One ounce = 0.062 lb |

| One kg = 2.204 lb | One kg = 1000 gram |

| One ton = 1000 kg | One gram = 0.001 kg |

Unit Conversation

- One foot = 12 inches

- One foot = 0.304 meter

- One foot = 304.8 mm

- One foot = 30 cm

- One inch = 25.4 mm

- One inch = 2.54 centimeter

- One yard = 3 ft

- One yard = 36 inches

Slump Value for Different Concrete Work

Concrete Work | Slump Value in the mm |

| Mass Construction | 25-50 |

| Beams and Slabs | 12-25 |

| Cement Concrete Pavement | 30-75 |

| Deck of Bridge | 20-30 |

| Vibrated Concrete | 50-100 |

| Retaining Wall and Column | 75-150 |

Slump Value for the different Concrete

What are the basic things a Civil Engineer should know?

BASIC THINGS FOR THE CIVIL ENGINEERS.

1. Lapping in the reinforcement is not allowed for the bars having diameters more than Thirty Six mm.

2. The Steel Char maximum spacing is 1.00 m (or) One No per 1m2.

3. In the steel dowels, a rod minimum of twelve mm diameter should be used.

4. The Steel Chairs minimum of twelve mm diameter bars to be used.

5. Longitudinal reinforcement should not be less than 0.8% and more than Six % of gross C/S.

6. The minimum bars used for a square column are Four No and Six No for the circular column.

Thank You For Reading This Important Information. Get Benefits And Share With New Commers.

Junaid Iqbal.

10 Comments